- All

- Manufacturing

- Metals

- News

- Oil & Gas

- Production Intelligence

- Reliability Intelligence

- Sustainability Intelligence

AI Insights Unveiled: Nandan Mishra, Algo8 CEO, Explores AI’s Evolution on News9

AI Insights Unveiled: Nandan Mishra, Algo8 CEO, Explores AI’s Evolution on News9 28 December, 2023 Courtesy – NEWS9 Live Algo8 AI is proud to share a recent feature on our Founder and CEO, Nandan Mishra, in a dynamic discussion hosted by News9. The conversation, which delves into the global and Indian landscape of artificial intelligence, […]

Prof Emeritus Luk Van Wassenhove of INSEAD Joins Algo8 EU/UK Advisory Board

Prof Emeritus Luk Van Wassenhove of INSEAD Joins Algo8 EU/UK Advisory Board London – 21 October, 2023 Algo8, a leading provider of Industrial AI solutions, announced that Professor Emeritus Luk Van Wassenhove of INSEAD, a renowned expert in operations management, has joined its Advisory Board for Algo8 Europe. In his role as an advisor, Prof. […]

Predicting Power Requirement In Steel Manufacturing (EAF)

Predicting Power Requirement In Steel Manufacturing (EAF) Problem In the steel manufacturing industry, Electric Arc Furnace (EAF) and Ladle Refining Furnace (LRF) processes require substantial electrical power, supplied by captive power plants (CPPs). Striking a balance between power supply and the manufacturing demand is a complex task due to the variable nature of manufacturing processes and environmental factors. This often leads to surplus power generation, also […]

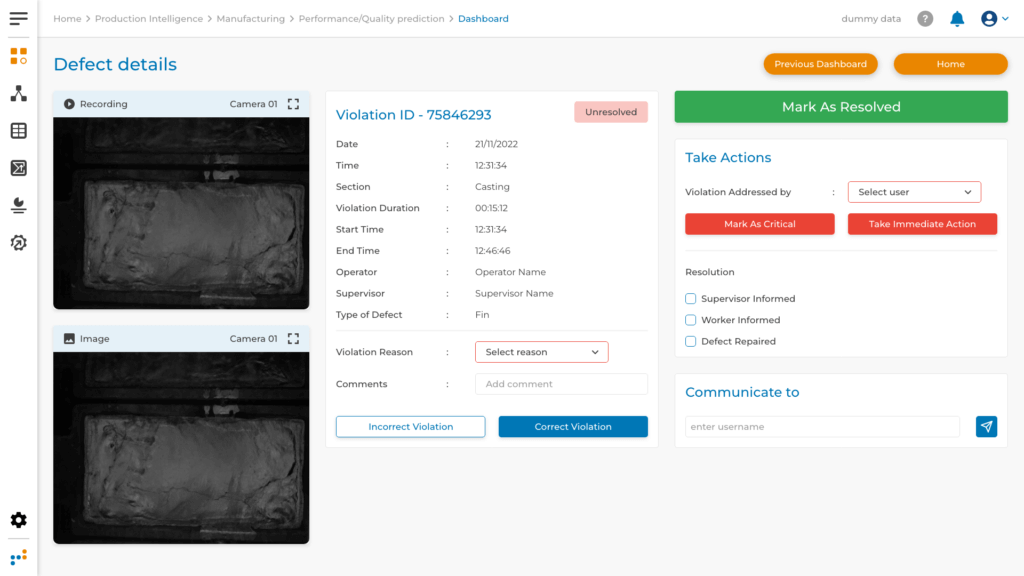

Real-Time Visual Inspection of Ingot Defects for the World’s Second Largest Integrated Zinc-Lead Producer

Real-Time Visual Inspection of Ingot Defects for the World’s Second Largest Integrated Zinc-Lead Producer Problem The world’s second-largest integrated zinc-lead producer faced significant challenges with its ingot production process. With a high production rate of 600 ingots per hour, manual quality control (QC) became impractical and hazardous for workers. The company needed a solution to […]

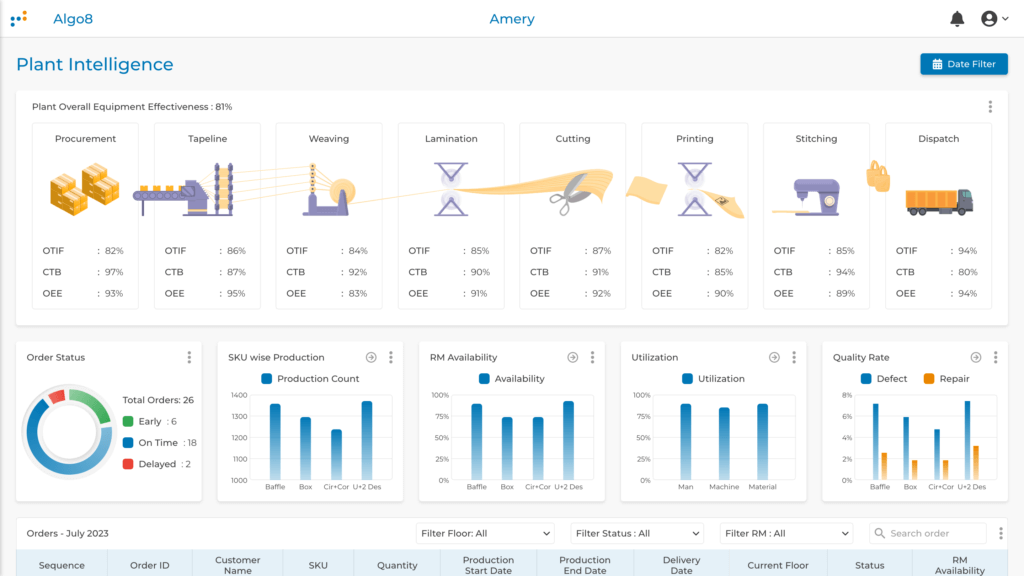

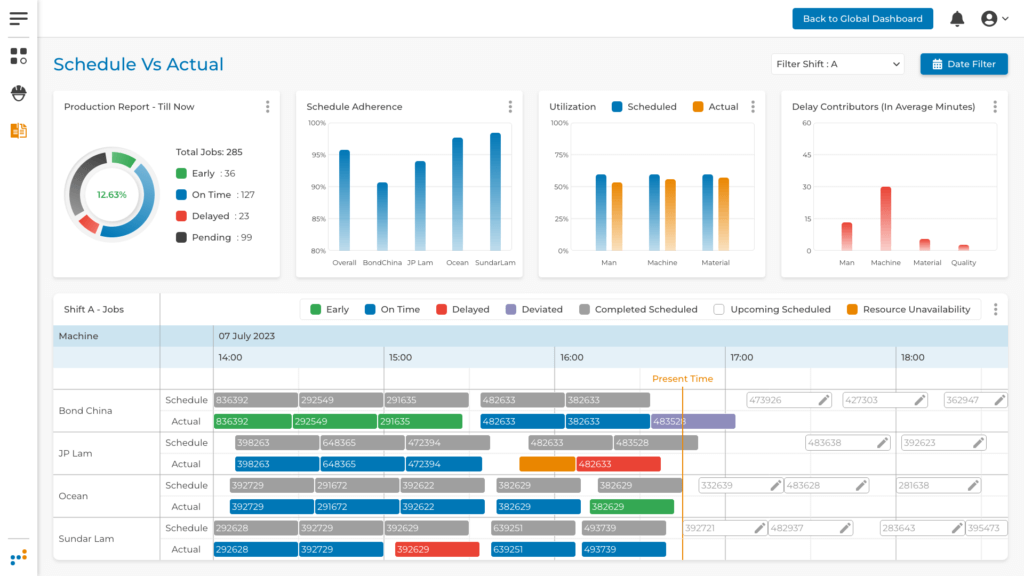

Streamlining Manufacturing Efficiency – Autonomous Production Planning & Scheduling

Streamlining Manufacturing Efficiency – Autonomous Production Planning & Scheduling Problem Many manufacturing companies face challenges with their manual production scheduling processes, leading to limited capabilities in handling complex multi-layer constraints and resulting in inefficiencies and suboptimal productivity. Static schedules often fail to accommodate changes in demand, machine breakdowns, or material availability, causing wasted resources and […]

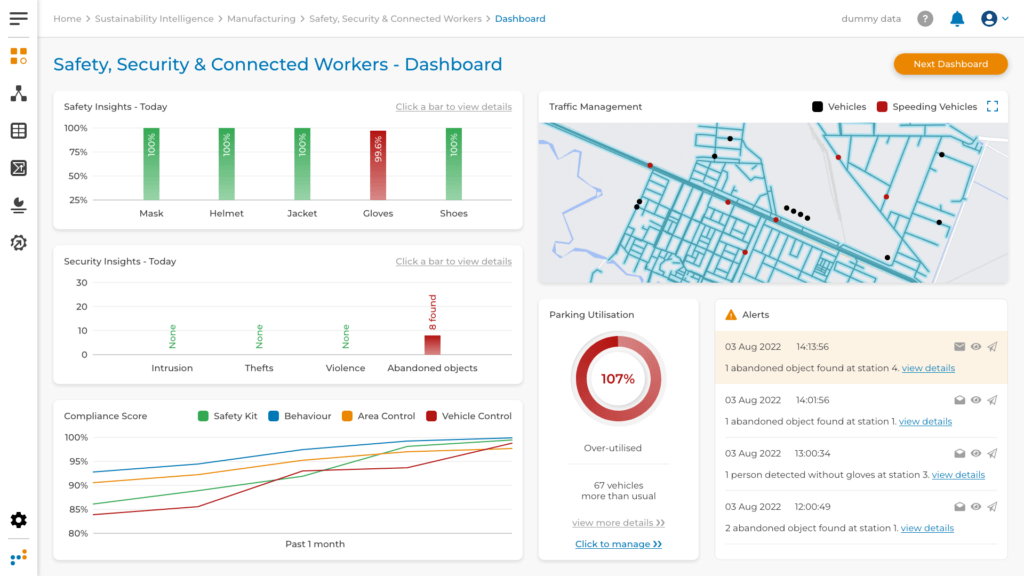

Safety, Security & SOP Compliance in Manufacturing

Safety, Security & SOP Compliance in Manufacturing Problem Safety and security are paramount in the manufacturing environment, where numerous hazards pose risks of accidents, injuries, and even fatalities. Manufacturing companies face several challenges in ensuring the safety, security, and compliance with standard operating procedures (SOPs): Applications To address the challenges and ensure safety, security, and […]

Smart Production Scheduling to Minimize Planning Losses and Material Losses

Smart Production Scheduling to Minimize Planning Losses and Material Losses Problem The production scheduling process is critical for optimizing resources, minimizing planning losses, and reducing material losses in manufacturing operations. However, traditional production scheduling methods may lack real-time visibility and flexibility, leading to inefficiencies, missed opportunities for optimization, and increased material wastage. The challenges faced […]

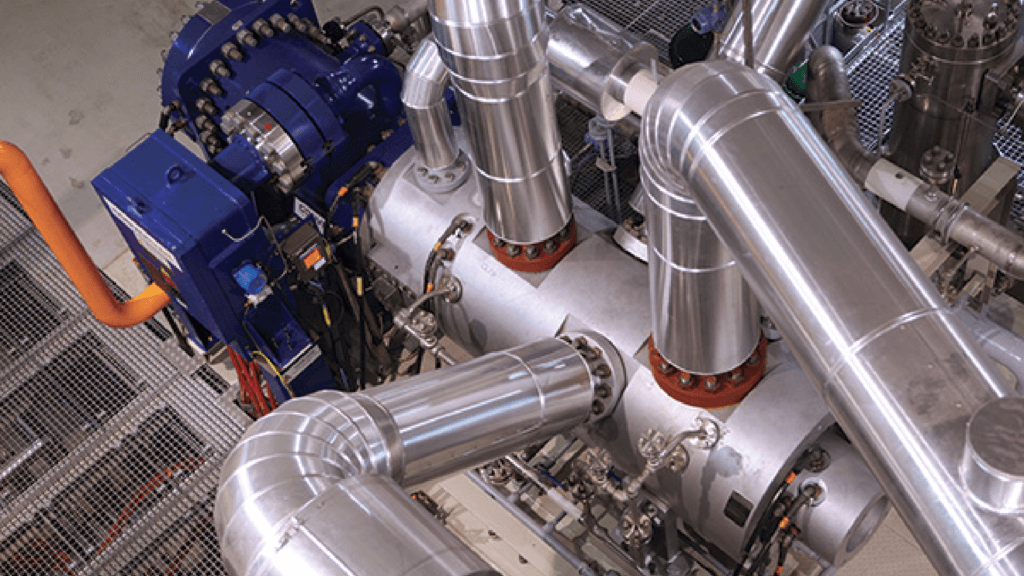

Rotating Equipment Condition Monitoring Maintenance & Fault Prediction using Wireless Sensors

Rotating Equipment Condition Monitoring Maintenance & Fault Prediction using Wireless Sensors Problem An industrial conglomerate faced challenges with their existing maintenance practices for rotating equipment, particularly screw compressors and their motors. Despite regular preventive maintenance processes and periodic vibration analyses, the company experienced a year-over-year increase in equipment failures. The delays in procuring components for […]

Real-Time Optimization of Refinery FCC

Real-Time Optimization of Refinery FCC Problem Optimizing plant performance is crucial to maximize output and achieve optimum profit, yield, production, and energy consumption without significant capital investments. However, many plants operate based on outdated design conditions and set points, leading to suboptimal performance. Additionally, the implementation of Advanced Process Control (APC) does not always result […]

Remote Plant Performance Monitoring for Ethylene Plant

Remote Plant Performance Monitoring for Ethylene Plant Problem Ensuring overall plant performance and individual system and equipment performances are crucial for achieving production targets, yield optimization, energy efficiency, and profitability in an ethylene plant. However, existing plant monitoring practices, predominantly based on Distributed Control Systems (DCS), lack real-time insights from the massive data generated. Many […]